LLS STI-P3 UNDERGROUND OWS

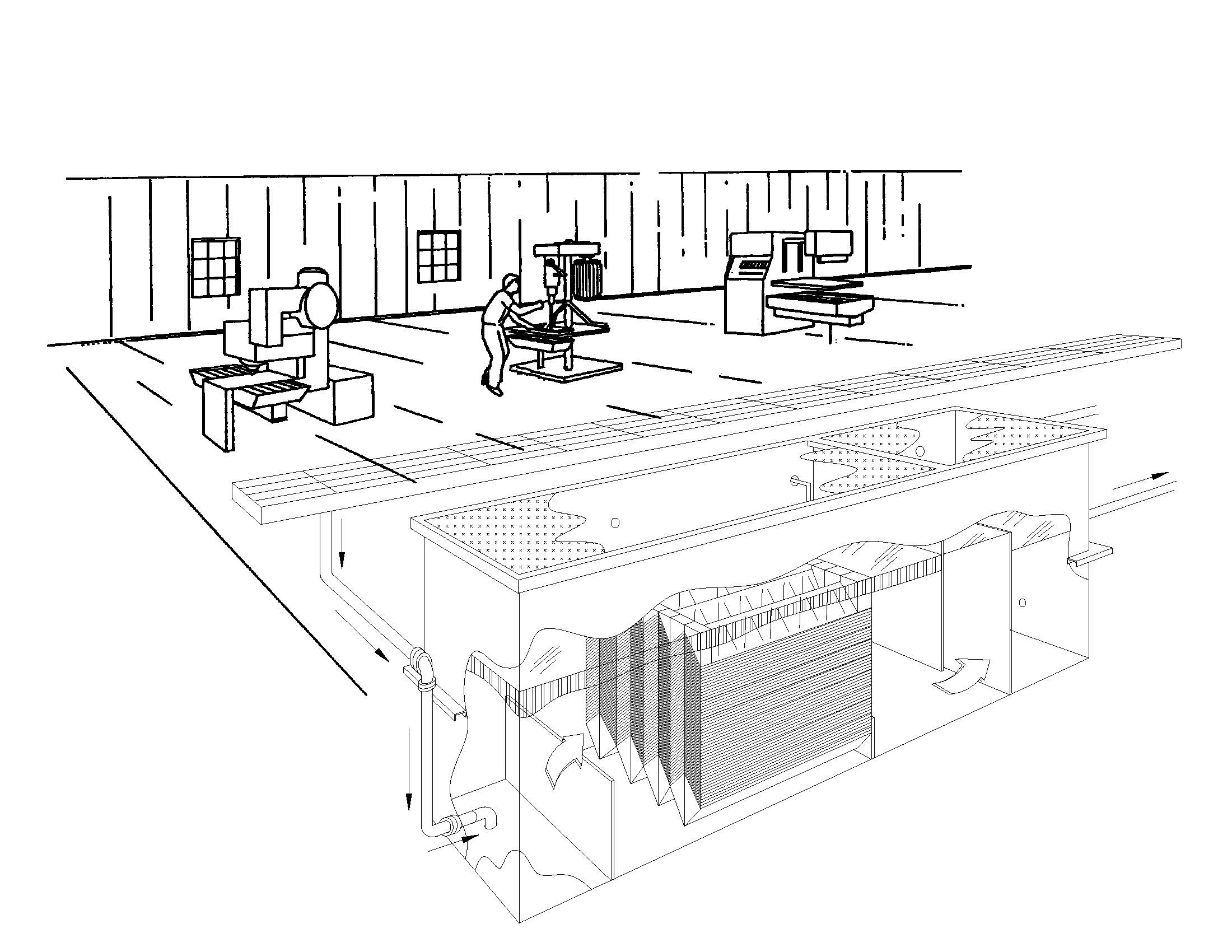

Increasing environmental regulations are affecting the activities of not only large corporations, but the small business owner as well. The LLS separator was designed to assist the small business owner in meeting these regulations where a larger separator is beyond both the need and the budget.

Applications:

- Vehicle Maintenance Shops

- Truck Stops

- Military Installations

Features:

- User Friendly! Floor plate covers allow for complete access to the tank interior for easy inspection,maintenance and oil removal.

- Designed to be placed underground, mounted in a concrete floor and coupled with a new or existing floor drain line.

- Each separator is provided with sacrificial anodes for cathodic protection..

- Standard construction is single wall. Double wall is available.

- MPak plate packs can be configured for flow rates between 15 - 50 GPM.

- Refer to Submittal Data Sheet