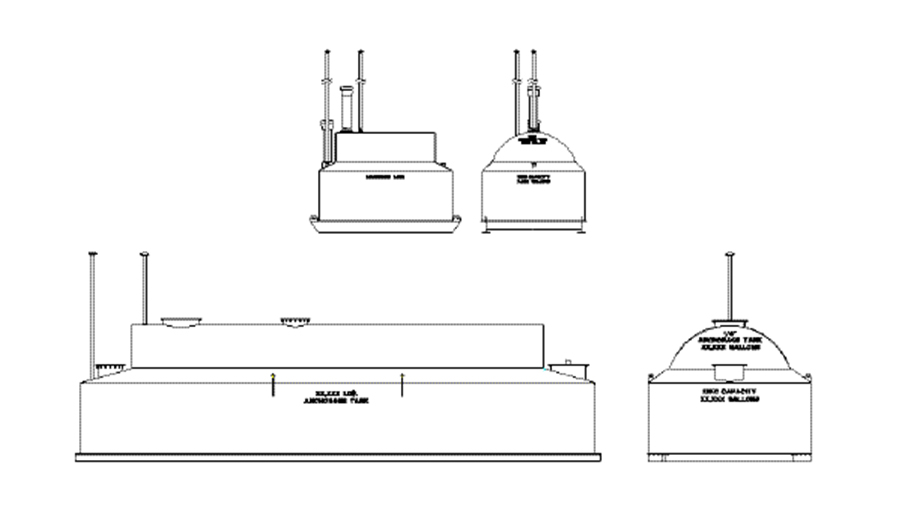

UL® LISTED CLOSED-TOP DIKED TANKS.

Features:

- Constructed to the requirements of UL® 142.

- Standard openings are female NPT, along tank top center-line.

- Exterior coating is a marine grade epoxy. Primary tank interior and dike interior are bare steel.

- Custom tanks, including special interior and/or exterior coatings, are available.

- Dimensions are approximate.

- Designed for stationary use only.

Details

| Anchorage Tank Model Number | Nominal Capacity (gallons) | Steel Gauge (primary) | Primary Tank (Diameter) | Primary Tank (Length) | Overall Width | Overall Length |

| AT5CDIKE | 500 | 10GA | 46″ | 6′-0″ | 4′-10″ | 8′-0″ |

| AT55DIKE | 550 | 10GA | 46″ | 6′-6″ | 4′-10″ | 8′-6″ |

| AT1MADIKE | 1,000 | 10GA | 46″ | 12′-0″ | 4′-10″ | 18′-0″ |

| AT1MBDIKE | 1,000 | 10GA | 64″ | 6′-0″ | 6′-4″ | 8′-0″ |

| AT15CDIKE | 1,500 | 3/16″ | 64″ | 9′-0″ | 6′-4″ | 12′-0″ |

| AT2MDIKE | 2,000 | 3/16″ | 64″ | 12′-0″ | 6′-4″ | 18′-0″ |

| AT25CDIKE | 2,500 | 3/16″ | 64″ | 15′-0″ | 6′-4″ | 22′-0″ |

| AT3MDIKE | 3,000 | 1/4″ | 76″ | 13′-0″ | 7′-4″ | 20′-0″ |

| AT4MDIKE | 4,000 | 1/4″ | 76″ | 17′-0″ | 7′-4″ | 24′-0″ |

| AT5MDIKE | 5,000 | 1/4″ | 96″ | 14′-0″ | 11′-0″ | 21′-0″ |

| AT6MDIKE | 6,000 | 1/4″ | 96″ | 16′-0″ | 11′-0″ | 23′-0″ |

| AT75CDIKE | 7,500 | 1/4″ | 96″ | 20′-0″ | 11′-0″ | 27′-0″ |

| AT8MDIKE | 8,000 | 1/4″ | 96″ | 22′-0″ | 11′-0″ | 29′-0″ |

| AT10MDIKE | 10,000 | 1/4″ | 96″ | 27′-0″ | 11′-0″ | 34′-0″ |

Utilization

Closed top diked above ground tanks are normally 10,000 – 35,000 gallons and are used at facilities storing more than 400,000 gallons of flammable or combustible liquids and regulated in accordance with 18-AAC-75.

Model ATDIKE Specification

Provide and install ____ Anchorage Tank Model AT___DIKE UL® listed closed top diked above ground storage tank for flammable liquids. The primary storage tank shall be approximately _____ in width, _____ in length, having a storage capacity of _____ gallons. The dike tank shall be approximately _____ in width, _____in length, having a storage capacity of _____ gallons.

Submittals

Provide shop drawings for the diked above ground storage tank that show principal dimensions, materials, and location of fittings.

General Characteristics

The closed top diked above ground storage tank consists of a horizontal cylindrical primary containment tank within a rectangular steel dike intended to contain product resulting from a spill, primary tank leak, or rupture. The entire tank system, including the beam support and dike tank, shall be listed by Underwriters Laboratories under UL®142 Standard For Safety as a complete, indivisible unit, and meet Seismic Zone 4 requirements.

Primary Tank

The primary storage tank shall be a horizontal cylindrical tank constructed in accordance with UL®142 Standard For Safety for steel above ground tanks for flammable or combustible liquids.

Dike Tank

Construction of the dike tank shall be such that the primary storage tank and its supports are integral with the dike, to prevent rotation or uplift of the A storage tank. Supports shall be constructed so that liquid can flow freely to the lowest level in the dike area. Stiffeners shall be provided on the top of all side walls. Buttresses used to stiffen the side walls must be at least the thickness of the side walls. The actual dike capacity shall be at minimum 110 % of the actual capacity of the primary storage tank.

Closed top dikes shall be provided with steel covers over the dike area to keep precipitation, debris, or other elements from entering the dike area, while allowing for inspection. Covers shall be constructed so as to reduce the risk of injury to persons during intended use. The dike shall be designed such that it cannot be pressurized, should fittings be capped.

Beam Support

The beam support shall be constructed of structural steel beam and shall be listed as an integral part of the tank.

Weld Joints

All joints on the primary storage and dike tanks shall be that required by Anchorage Tank’s UL®142 listing. In addition, non-structural external seams shall be seal welded before coating. All weld spatter shall be removed and all sharp edges shall be rounded and smoothed by grinding.

Tank Attachments and Penetrations

Piping penetrations through the primary storage tank shall be made only through the top center line of the tank. Each tank shall be equipped with a minimum of four lifting eyes adequate for the safe handling of the tank during installation.

Dike Drain

The dike tank shall include a drain so that spilled fuel may be removed. The drain assembly shall consist of a two inch schedule 80 pipe nipple six inches long, reinforcing plate and a 2″ forged Vogt OS&Y gate valve. The pipe nipple and reinforcing plate shall be welded to the dike tank wall. The gate valve shall be welded to the pipe nipple. Connected to the gate valve shall be a stainless steel dry-break coupler and adapter. (refer to attached drawing)

Primary Tank Fill

The primary tank storage fill connection shall be enclosed in a steel containment box mounted on the dike tank wall. Inside this box, the fuel truck connection point shall utilize a stainless steel dry-break coupler and adapter, a flanged gate valve, and a flanged swing check valve. (refer to enclosed drawing) The primary storage tank shall be equipped with a hydraulically dampened overfill protection valve set to positively stop flow to the tank at 90% capacity level. A high level alarm and strobe light shall also be provided to activate at 85% capacity, as well as a gauge, both to be visible from the tank fill point.

Venting

The primary storage tank and dike tank shall be equipped with atmospheric and emergency venting in accordance to UL®142.

Monitoring Dike Space

The dike tank area shall be equipped with a leak detection probe connected to a readout panel with alarm.

Alarm Control Panel

All tank fill alarms, pipe leak detection alarms, and dike tank leak detection alarms shall be connected and run to a control panel. All electrical wiring shall conform to NEC.

Access Manholes

The primary storage tank and the dike tank shall contain a bolt-down manhole to provide access to the interior of the tanks to facilitate nondestructive testing. Manholes must be a minimum of 30″ in diameter.

Ladders and Runways

Tanks with manway access shall be provided with ladders that comply with the construction requirements of OSHA standards. The climbing surfaces must be vertical and directly in line with the edge of the tank manhole.

Runways (catwalks) shall comply with the construction requirements of OSHA standards. Runways used below the top level of the tank are only required to have a guardrail on one side.

Inspection & Testing

Each tank, before coating, shall be tested per UL®142 by Anchorage Tank to determine that the tank doesn’t leak. If leaks are noted during the test, they shall be repaired by re-welding and the tank retested.

Coating

Before application of coatings, all surfaces shall be cleaned and prepared by sandblasting in accordance with Steel Structures Painting SSPC-3. The primary storage tank and dike tank exterior surfaces shall have a protective coating system, Madison Acryathane or approved equal, applied in accordance with the coating manufacturer’s recommendations. The primary storage tank interior shall be coated with Madison Petroliner, or approved equal, applied in accordance with the coating manufacturer’s recommendations. The dike tank interior, as well as the exterior surface of the primary storage tank encompassed within the dike, shall be coated with Devoe Devan 720 epoxy, or approved equal, applied in accordance with the coating manufacturer’s recommendations.