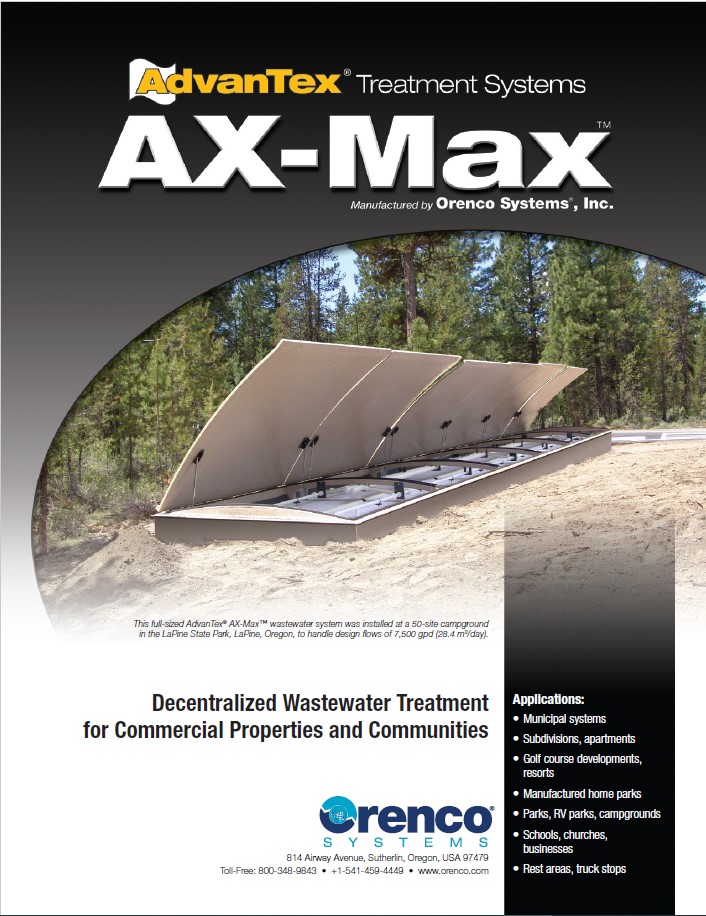

AdvanTex® AX-Max™ Treatment Systems

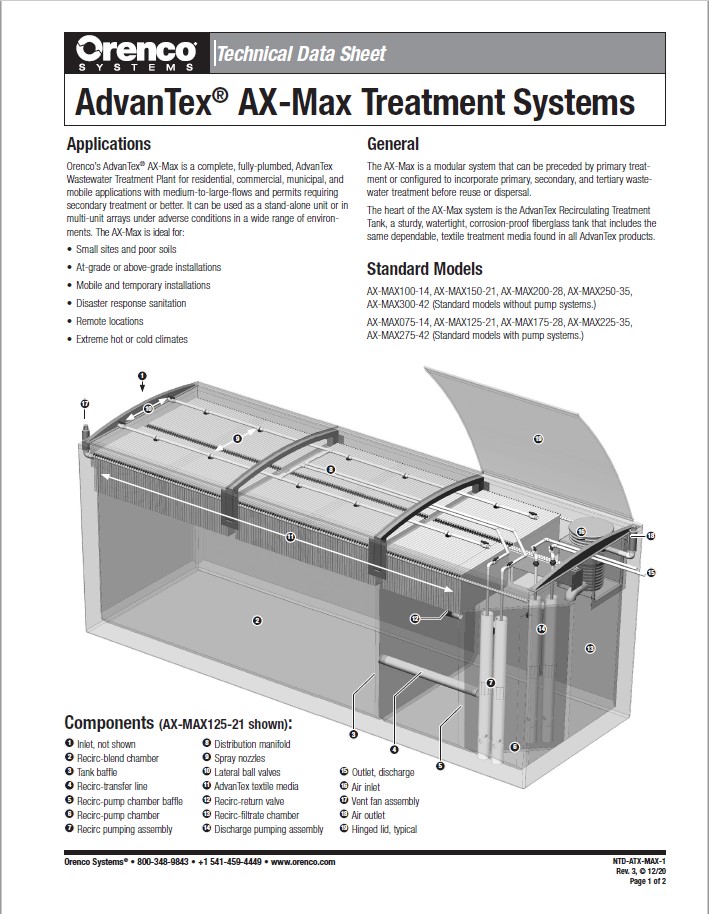

Orenco’s AdvanTex® AX-Max™ Treatment Systems are a dependable, proven technology for treating domestic-strength, primary-treated effluent to better-than-secondary standards, including nitrogen-reduction. They consist of sturdy, watertight fiberglass tanks that incorporate recirculation-blend and discharge tankage in a single module. Each complete, pre-manufactured unit also includes pumping systems, ventilation, and a lightweight, highly absorbent, engineered textile media that treats a tremendous amount of wastewater in a small space.

Applications

AX-Max™ Treatment Systems are intended for large residential applications or for commercial and municipal applications that require advanced secondary treatment. They eliminate the need for separate recirculation and discharge tanks by performing both functions within a single module. AX-Max™ units are ideal for subdivisions, “fringe” development, hotels, resorts, schools, churches, businesses, manufactured home parks, RV parks, campgrounds, rest areas, and truck stops.

Flows

Depending on model, a single AdvanTex® AX-Max™ unit can treat peak flows of 5,000-15,000 gpd. AdvanTex® Treatment Systems are modular, however, and can be installed in multi-unit arrays to handle higher flows.

Details

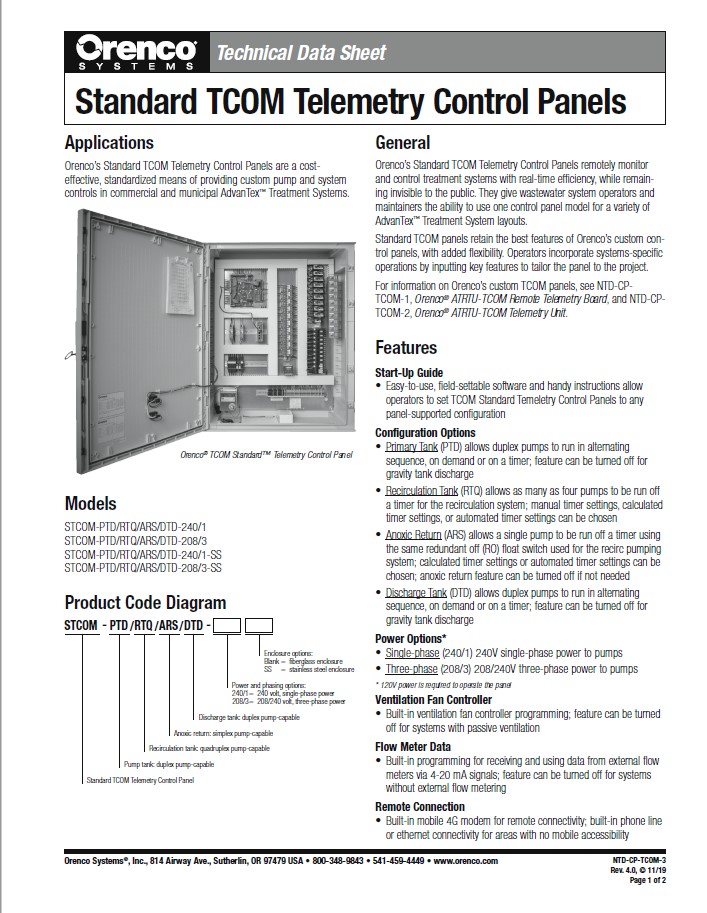

Controls for Commercial AdvanTex® Wastewater Treatment

Orenco Controls, a division of Orenco Systems, engineers standard and custom control panels, designed specifically for your project. Every effort is made to utilize a standard panel but historically, systems in Alaska have required a custom approach. Either way, we have you covered.

Orenco Controls is a fully-equipped UL508A / UL698A shop that includes:

- State-of-the-art equipment for high-volume production: wire prep machine, crimper, calibrated assembly tools, equipment for load testing at all voltages and phases (single- and three-phase)

- In-house custom terminal marking, label engraving, metal mounting plate fabrication, and complete machine shop operations

- Full certification for UL508A and UL698A (Hazardous Location) requirements

Commercial systems employ the TCOM remote telemetry units that give facility managers, operators, and service providers the ability to remotely monitor and control the performance of mechanical equipment in real time.

Projects

Kenai River Max System

The phone conversation began with, “Do you have a system that can withstand a flood?” Yes, we do. We call it the Mini-Max. This configuration combines the primary treatment (septic tank), secondary treatment (AdvanTex® filter fabrics), and tertiary treatment (UV on the discharge) in one watertight box. The Mini-Max is fabricated in the same manner as the larger MAX units and available in lengths of seven-foot increments.

Three couples pooled their resources to build this home on stilts alongside the river but the area is prone to annual flooding and many homes in the area struggle with holding tanks where traditional septic systems are prohibited. The home has three master bedrooms used year-round and the entertaining of guests is a certainty so it was determined a 14’ long unit would be required.

The unit is set into the ground under the home so floodwaters can simply flow around it. Wastewater drops down from above and treated effluent gravity flows into a gravel swale 150 feet from the river. A standard residential VeriComm® control panel allows for remote monitoring.

Kitoi Bay Hatchery Max System

Kodiak Regional Aquaculture Association needed a wastewater treatment solution for their Kitoi Bay Hatchery on Kodiak Island. The Hatchery consisted of several residential and bunkhouse buildings with existing septic tanks that shared a common marine outfall. It was determined that secondary and tertiary treatment would be needed to meet state wastewater standards.

A fourteen feet long AdvanTex® MAX unit was selected to handle this task. The effluent from all the existing septic tanks (primary treatment) was gathered into one outfall pipe and the MAX was installed on the beach to intercept this flow. AdvanTex® filter fabrics provided secondary treatment and a triple UV lamp handled tertiary treatment with the prefabricated units set into the slope of the beach. A new underwater outfall line was installed.

With telephone service to Kitoi Bay a future hope, a T-COM control panel was employed with a touchscreen interface so the onsite operator can easily check the system.