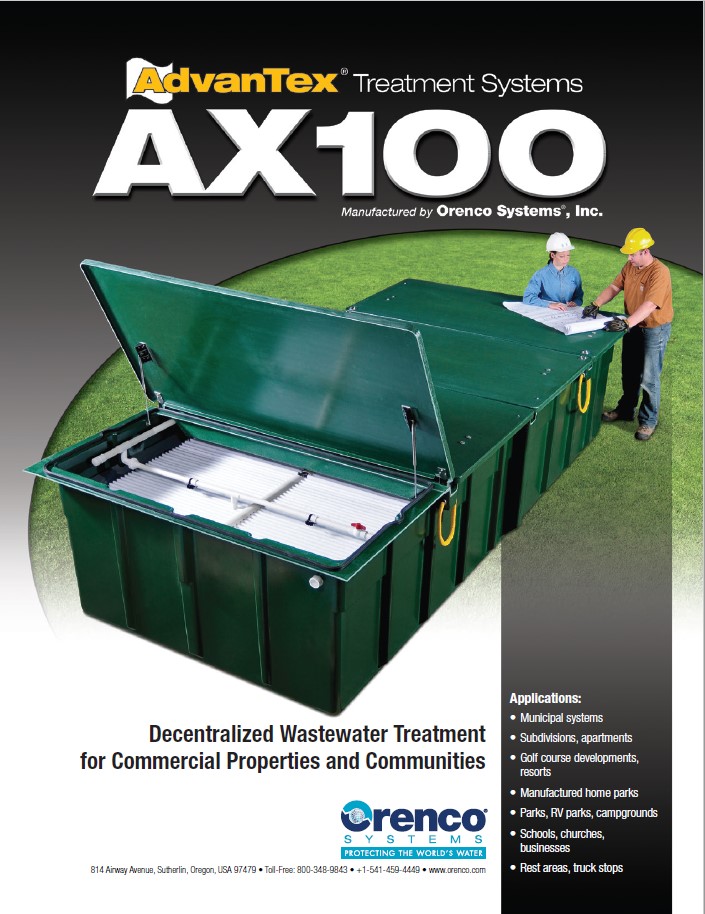

AdvanTex® AX-100 Treatment Systems

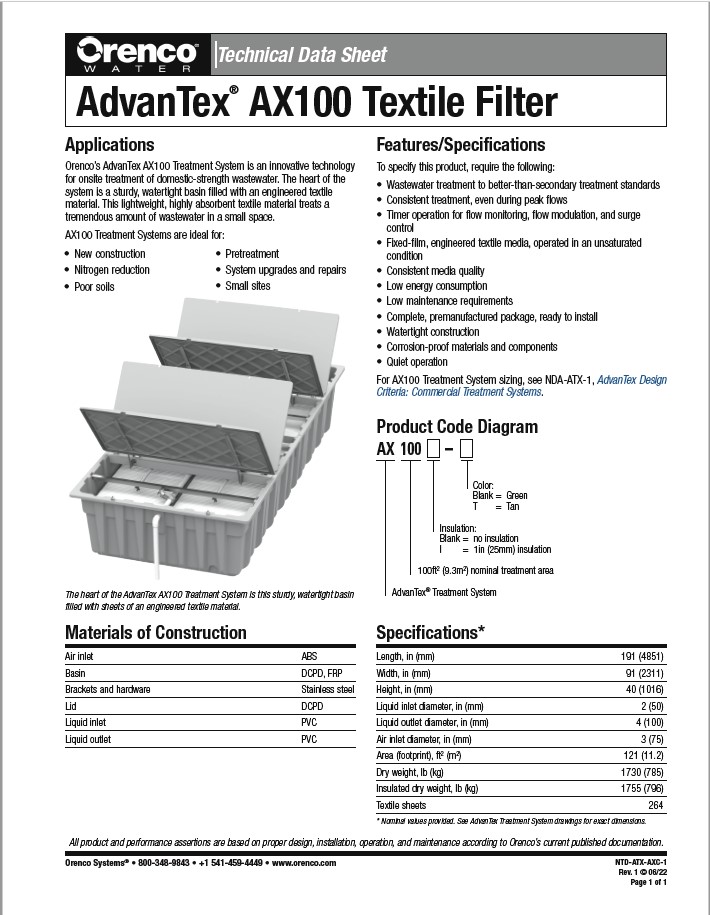

Orenco’s AdvanTex® AX-100 Treatment Systems are a dependable, proven technology for treatment of primary-treated effluent to better-than-secondary standards, including nitrogen-reduction. AX-100 treatment units consist of sturdy, watertight basins filled with a lightweight, highly absorbent, engineered textile media that treats a tremendous amount of wastewater in a small space.

Applications

AX-100 Treatment Systems are intended for large residential applications or commercial and municipal applications that require an advanced secondary treatment system. They’re also an excellent choice for decentralized settings, including new installations, retrofits, or repairs. AX-100s are ideal for subdivisions, “fringe” development, hotels, resorts, schools, churches, businesses, manufactured home parks, RV parks, campgrounds, rest areas, and truck stops

Flows

A single AdvanTex® AX-100 pod can treat flows of up to 5000 gpd. AdvanTex® Treatment Systems are modular, however, and can be installed in multi-pod arrays to handle higher flows.

Details

This example 4,000 gallons per day system is designed to handle the wastewater from 20-23 homes in a lake-front subdivision. A downhill lot was used for the treatment system. Each home has its own steel septic tank where the effluent gravity flows into a lift station tank down the street. The lift station sends the septic tank effluent up to a 12,000-gallon steel recirculation tank. Two AdvanTex® AX100 filters treat the effluent before it is discharged to the pressurized drainfield.

Each home has its own septic tank that may either pump or gravity flow the effluent down the street to the treatment system. In this Example subdivision, each home can gravity flow. The homeowners have more lawn free for their own use since there are no drainfield pipes to work around.

The AdvanTex® Treatment System is located down the street. Effluent from each home’s septic tank flows downhill to a lift station tank. From there the effluent is pumped into a 12,000-gallon recirculation tank. Two more pumps send the effluent into AX100 filter pods at regular intervals. When this tank reaches capacity, the filtered effluent is redirected to a 2,000-gallon discharge tank. At regular intervals throughout the day, the filtered effluent is pumped out to the drainfield for final disposal under the RV storage parking lot.

The developer would set up a homeowners association that owns the water well and wastewater treatment system as a private utility. The association dues pay for the system monitoring and maintenance.

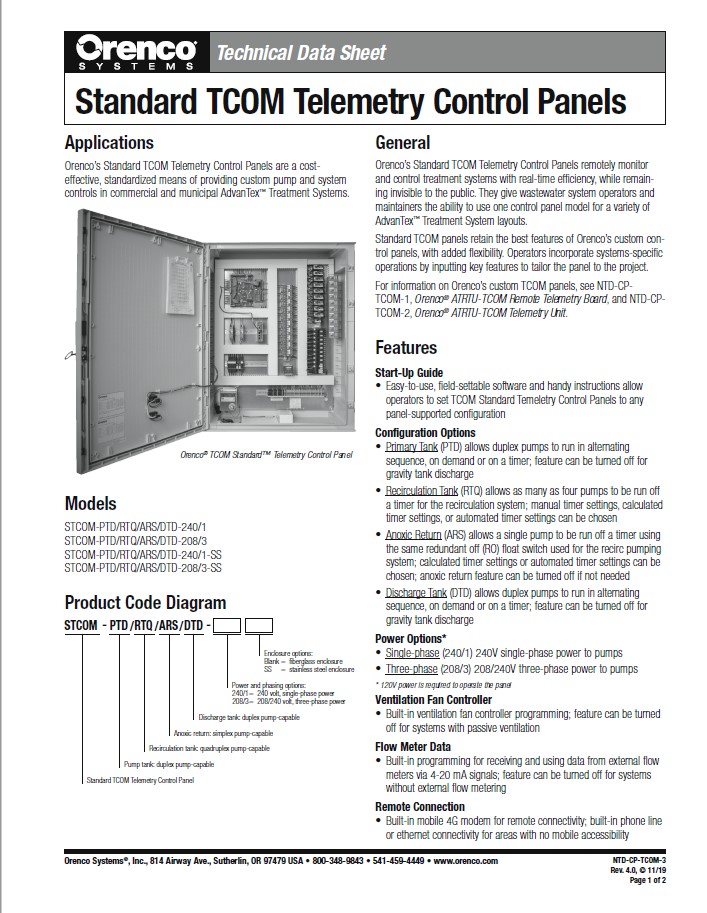

Controls for Commercial AdvanTex® Wastewater Treatment

Orenco Controls, a division of Orenco Systems, engineers standard and custom control panels, designed specifically for your project. Every effort is made to utilize a standard panel but historically, systems in Alaska have required a custom approach. Either way, we have you covered.

Orenco Controls is a fully-equipped UL508A / UL698A shop that includes:

- State-of-the-art equipment for high-volume production: wire prep machine, crimper, calibrated assembly tools, equipment for load testing at all voltages and phases (single- and three-phase)

- In-house custom terminal marking, label engraving, metal mounting plate fabrication, and complete machine shop operations

- Full certification for UL508A and UL698A (Hazardous Location) requirements

Commercial systems employ the TCOM remote telemetry units that give facility managers, operators, and service providers the ability to remotely monitor and control the performance of mechanical equipment in real time.

Projects

Mat-Su Career Center Wasilla, Alaska

The Mat-Su Career & Technical High School in Wasilla, Alaska is a career and technical high school that opened Fall 2007.

The 5,000 gallons per day septic system is an AdvanTex® Treatment System composed of a 20,000-gallon steel single-compartment processing tank with a 7,500-gallon steel recirculation tank and a 2,850-gallon compartment for filtered effluent discharge. The system also uses three AX100 filter pods and a telemetry-enabled control panel.

Automatic Distribution Valve

Each time the pump is activated, the distribution valve sends the liquid to a different AX100 filter pod, evenly sharing the filtration.

Pod Drainage Piping

Drains of AX100 filter pods are piped together.

Pods Prepared for Spray-On Insulation

Piping is supported in preparation for spray-on foam insulation on all sides of the AX-100 filters.

Tanks in Place

Tanks are already in position. AX-100 filter pods have been delivered to the site. Access risers are mounted on tanks.

Tanks Ready for Back Fill

Ventilation Line from Pods

Ventilation lines for the AX100 filter pods are piped together.

Werre Subdivision, Chugiak, Alaska

This 2,500 gallons per day system is designed to handle the wastewater from nine homes in a ten-lot subdivision. The tenth lot was used for the treatment system. Each home has its own steel septic tank where the effluent gravity flows into a centrally located lift station tank. The lift station sends the septic tank effluent up to a 4,000-gallon steel recirculation tank with an extra 1,500-gallon compartment for filtered effluent discharge to one of two drainfields. One AdvanTex® AX100 filter treats the effluent. The entire system was elevated to maintain separation from groundwater.

The developer set up a homeowners association that owns the water wells and wastewater treatment system as a private utility. The association dues pay for the system monitoring and maintenance.

A system like this is a great alternative for subdivisions. Each lot has its own septic tank for primary treatment but the drainfield and secondary treatment are located elsewhere.

Delivering the AX100 Pod

The pod is carefully lifted off the truck and placed in position.

Drainfield

There is a drainfield on each side of the system so there is always a spare.

November System Startup

It was ten degrees out that day. At least the wind wasn’t blowing.

Startup

Calibrating the AX100 pod during system start-up.

Joe Redington Jr./Sr. School Wasilla, Alaska

The Joe Redington, Sr. Jr/Sr High School in Wasilla, Alaska school opened Fall of 2015.

The 5,500 gallons per day septic system is an AdvanTex® Treatment System composed of a 20,000-gallon steel single-compartment processing tank with a 7,500-gallon steel recirculation tank and a 2,000-gallon compartment for filtered effluent discharge. The system also uses three AX100 filter pods and a telemetry-enabled control panel.

This is the second time the Mat-Su Borough School District has chosen AdvanTex® to reduce the footprint of onsite wastewater treatment for their rural schools.

Completing the piping between pods and tank risers. Next step is to spray urethane foam insulation and top coat around pod sides.

Preparing the pods for spray urethane insulation before backfill.

System is backfilled, ready for start-up inspection.

During Start-Up Inspection, pods are checked and water pressure calibrated for even distribution of wastewater from the tanks below. Each lid section has insulation enclosed within the fiberglass.

The School District Maintenance Crew specified 48” diameter tank risers to provide plenty of access to the system piping. Everything is designed to be reached from above so there’s no need to enter the tank.

At the completion of Start-Up Inspection, the system is closed and all hatches bolted for safety.