OVERFILL PREVENTION - EPA COMPLIANCE

Filling the tank.

When specifying a fill limiting device, it is helpful to know what equipment is used by the personnel filling the tanks at the site.

Tanks equipped with the Clay and Bailey F-30 or F-40 may be filled with either a nozzle or a dry break connection.

Allow 23" for float arm to swing freely. Drop tube not shown

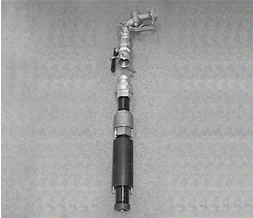

Clay & Bailey F-30 (2") and F-30 (4")

- Aluminum body with 2" NPT male connection.

- F-30 flow rate of 200 GPM @ 40 PSI.

- F-40 flow rate of 300 GPM @ 40 PSI.

- Adjustable fill tube collar permits custom shutoff level for any AST.

- Entirely mechanical in operation, no power source is required.

- No line shock is experienced during delivery or shutdown.

Filling the tank.

When specifying a fill limiting device, it is helpful to know what equipment is used by the personnel filling the tanks at the site.

Tanks equipped with the Morrison 9095 can only be filled with a nozzle equipped a dry break connection. Pressure from the fill hose is necessary to open the poppet valve inside the fill limiter.

Allow 23" for float arm to swing freely. Drop tube not shown

Morrison 9095 A (2")

Installed at the fill port and shuts off the flow at a preset level (90% tank capacity maximum). Mounts on a standard 4" NPT male connection. Fill connection is standard 2" male cam-and-groove fitting. The vertical float makes this valve ideal for smaller tanks, where space for fittings is at a premium.

- One piece anodized aluminum adaptor

- Full flow up to shut off

- No shock or kickback

- Float movement is vertical. No swing extensions to get hung

- Stainless steel linkage

- No outside power source is needed